Safety and Health — Massachusetts

Both federal and Massachusetts laws govern workplace safety and health. The federal Occupational Safety and Health Act (OSH Act) imposes a number of requirements on employers to create a safe workplace. It grants the Occupational Safety and Health Administration (OSHA) the authority to create rules, standards, and regulations to govern workplace safety and health.

In addition to OSHA, the Massachusetts Division of Occupational Safety (DOS) enforces regulations governing certain safety-related aspects of the workplace. These regulations govern worksites that manage asbestos, lead, and other high-risk materials.

Coverage

The OSH Act broadly covers almost all private-sector employers. On March 9, 2018, the governor of Massachusetts signed into law a statute that makes the OSH Act requirements applicable to public-sector employers.

Certain limited entities are exempt from the OSH Act.

Employers

The OSH Act applies to almost all private-sector employers and employees, including religious entities to the extent that the workers perform non-religious work.

The limited exemptions from OSHA coverage include:

- state and local government employers

- self-employed individuals

- farmers who do not employ workers outside of the immediate family.

Employees

The OSH Act applies to almost all private-sector employees. Its coverage includes executives and managers. However, in most circumstances, coverage does not extend to employees whose working conditions are regulated by other provisions of federal law, such as:

- mining workers

- certain truckers and trasportation workers

- atomic energy workers.

Multi-employer workplace liability

In several industries, multiple employers perform work at the same worksite. For instance, a construction project may engage a general contractor and numerous subcontractors at the same worksite. To address safety and health issues at multi-employer worksites, OSHA and the courts apply a doctrine to determine when more than one employer may be cited for an unlawful, hazardous condition at a worksite.

OSHA recognizes four circumstances where an employer may be held liable under this doctrine:

- The "creating employer" - The employer causes the hazardous condition that violates the OSHA standard.

- The "exposing employer" - The employer’s own employees are exposed to the hazard.

- The "correcting employer" - The employer is engaged in a common undertaking on the same worksite as the exposing employer and is responsible for correcting a hazard.

- The "controlling employer" - The employer has general supervisory authority over the worksite, by contract or by the exercise of practical control, including the power to correct safety and health violations or to require others to correct them.

The requirements of a controlling employer have been the focus of most discussion by OSHA and the courts. Significantly, the controlling employer has a lesser duty to exercise reasonable care than an employer that must protect its own employees. Various factors affect how frequently and closely a controlling employer must inspect its worksite to meet its standard of reasonable care, including:

- the scale of the project

- the nature and pace of the work, including the frequency with which the number or types of hazards change as the work progresses

- the controlling employer’s knowledge about the safety history and safety practices of the employer it controls and about that employer’s level of expertise.

More frequent inspections are typically needed if the controlling employer knows that the other employer has a history of noncompliance, or if the controlling employer has never worked with the other employer and does not know its compliance history. Less frequent inspections are appropriate where the controlling employer sees indications that the other employer has implemented effective safety and health efforts. A high level of compliance by the other employer is an important indicator of effective safety and health efforts. Other important safeguards for controlling employers include the use of an effective, graduated system of enforcement for noncompliance with safety and health requirements coupled with regular jobsite safety meetings and safety training.

Employers affiliated with a multi-employer worksite should take steps to limit their OSHA liability for injuries on the worksite. These steps include:

- drafting unambiguous contract provisions to clearly allocate responsibility for safety and health compliance at the worksite

- investigating the safety and health history and competence of other employers at the worksite

- routinely inspecting the worksite to ensure OSHA compliance and immediately correct any potential hazards

- implementing an effective system for promptly correcting hazards (including designation of a specific individual employed by the contractor to address and resolve safety issues)

- enforcing the contractor’s compliance with safety and health requirements with an effective, graduated system of enforcement (a system that provides for warning, penalties, and ultimately, termination of the contract for safety violations) and follow-up instructions.

Requirements

Covered employers must adhere to a number of general requirements and specific recordkeeping and reporting requirements to comply with the OSH Act.

General requirements

Employers are responsible for the following under the Occupational Safety and Health Act:

- meeting the general duty to provide a workplace free from recognized hazards

- keeping workers informed about OSHA safety and health matters

- complying in a responsible manner with standards, rules, and regulations listed under the OSH Act

- familiarizing themselves with mandatory OSHA standards

- making copies of standards available to employees upon request

- evaluating workplace conditions

- minimizing or eliminating potential hazards

- cooperating with OSHA compliance officers

- not discriminating against employees who properly exercise their rights under the OSH Act

- reducing the number of citations within the prescribed period

- providing employees safe, properly maintained tools and equipment, including personal protective equipment, and making sure that employees use this protective equipment

- warning employees of potential hazards

- establishing and updating operating procedures and communicating these operating procedures to employees

- providing medical examinations when required

- providing the training required by OSHA standards

- complying with OSHA recordkeeping and reporting requirements

- posting the OSHA “It’s The Law” poster at a prominent location within the workplace

- posting OSHA citations and notices stating that the employer has corrected any safety or health hazard (“abatement verification notices”) at or near the worksite involved

- providing employees, former employees, and their representatives access to a log of work-related occupational injuries and illnesses

- providing employees and others access to employee medical records and exposure records.

Recordkeeping

All employers are required to keep records of occupational deaths, injuries and illnesses, and to make certain reports to OSHA. Smaller employers (with 10 or fewer workers) and employers who have establishments in certain retail, service, finance, real estate, or insurance industries are not required to keep those records. However, smaller employers must report any occupational fatalities or catastrophes to OSHA, and they must participate in government surveys on request.

Reporting fatalities and multiple hospitalization incidents

Within eight hours of either:

- the death of an employee from a work-related incident

- the in-patient hospitalization of three or more employees as a result of a work-related incident

the employer must report the fatality or hospitalization by using at least one of the following methods:

- telephone to the nearest OSHA Area Office

- calling the OSHA toll free central reporting number: (800) 321-OSHA.

If the relevant office is closed or the employer is otherwise unable to speak to a person at the office, the employer must use OSHA’s central reporting number to report the accident. The employer may not report the incident by leaving a message on an office’s answering machine, faxing the office, or sending an email. If the employer does not learn of the incident right away, it must make the report within eight hours of the time that it learns of the incident.

For each fatality or multiple hospitalization incidents, the employer must provide OSHA with all the following information:

- the name of the company

- the location of the incident

- the time of the incident

- the number of fatalities or hospitalized employees

- the names of any injured employees

- the company contact person and his or her phone number

- a brief description of the incident.

Other recordkeeping and reporting requirements

Recordable injuries

The employer also must prepare and maintain records of "recordable" injuries and illnesses.

An injury or illness is "recordable" when:

- the incident is work related

- the incident is a new case

- the incident meets at least one of the following criteria:

- The incident results in death, days away from work, restricted work or transfer to another job, medical treatment beyond first-aid, or loss of consciousness.

- The incident involves a significant injury or illness diagnosed by a physician or other licensed healthcare professional.

- The incident is a needle stick injury or cut from a sharp object that is contaminated with another person’s blood or other potentially infectious material.

- The injured employee is medically removed under the medical surveillance requirements of an OSHA standard.

- The employee suffers from hearing loss.

- The employee has been exposed to and is subsequently infected with tuberculosis within the workplace.

- Note: OSHA has identified that COVID-19 cases in the workplace are recordable illnesses.

Incident reports and Form 301

Within seven calendar days of receiving information that a recordable injury or illness has occurred, the employer must enter information regarding the incident on OSHA Form 300 (injury and illness log) and must complete OSHA Form 301 (incident report). At the end of the year, the employer must review the injury and illness log to verify its accuracy and summarize it on OSHA Form 300A. A company executive must certify Form 300A and the employer must post it for three months, from February 1 to April 30 of the following calendar year. Employers must retain all of these forms for five years following the calendar year to which they relate. These forms are available at:

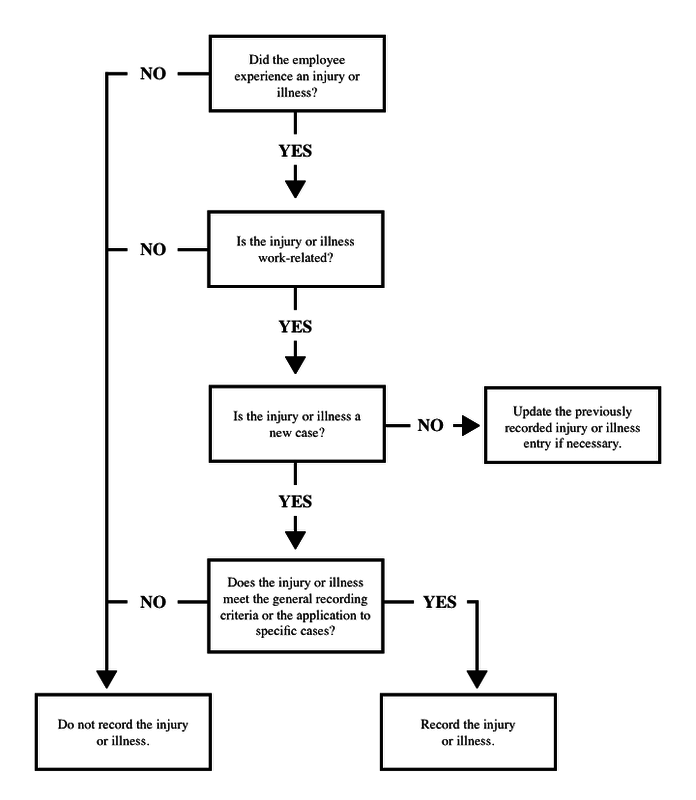

An employer should follow these steps in the flowchart that follows to determine whether an injury is recordable.

Exposure to toxic materials

An employer must maintain records of an employee’s exposure to potential toxins and related medical records for the duration of the individual’s employment, plus at least 30 years. The employer must grant access to these records to employees exposed to potential toxins. If the employer has medical examination documents, the employer must treat the documents as confidential and keep them separately from the employee’s personnel file.

Standards

The Occupational Safety and Health Administration (OSHA) issues safety and health standards to address specific workplace hazards. These standards require employers to maintain certain conditions and practices to protect their employees. Employers must familiarize themselves with applicable standards and comply with them. For instance, OSHA has issued standards that require employers to provide proper personal protective equipment (with a few exceptions) to employees at no cost. The limited exceptions to this statute include:

- ordinary safety-toed footwear

- ordinary prescription safety eyewear

- logging boots

- ordinary clothing and weather-related gear.

When OSHA does not include specific standards, employers must still comply with the OSH Act’s general duty clause.

Specific standards

OSHA’s standards cover numerous workplace hazards. Some of the common hazards that it regulates include:

- toxic substances

- harmful physical agents

- electrical hazards

- machine hazards

- fall protection

- workplace sanitation

- blood borne pathogens

- equipment, tool and machine guarding

- hazardous waste

- infectious diseases

- fire and explosion hazards.

General duty clause

The OSH Act’s general duty clause requires employers to “furnish … a place of employment which is free from recognized hazards that are causing or are likely to cause death or serious physical harm to employees.” Accordingly, employers must maintain safe, hazard-free workplace conditions regardless of whether specific standards apply to it. Even if an employer has not discovered a specific hazard, OSHA considers the hazard “recognized” under this clause when its existence and the means to correct it are known in the employer’s industry.

Variances

At the request of an employer, OSHA may grant permission to deviate from the requirements of a standard by issuing a variance. Variances may be temporary, permanent or experimental, depending on the circumstances. A temporary variance is one that provides an employer with time to come into compliance with the requirements of a standard. A permanent variance authorizes an alternative to a standard so long as the employees work in a safe and healthy workplace. OSHA issues experimental variances to employers to demonstrate or validate new and improved technology to protect employees.

Employers must meet specific requirements to obtain a variance from OSHA. For instance, to obtain a temporary variance from a newly-issued standard, the employer must demonstrate that it cannot fully comply with the effective date because of a shortage of materials, equipment or technical or professional personnel. When an employer seeks a permanent variance, it must demonstrate that its alternative protects employees to the same degree as the standard.

Other implications

Failure to comply with OSHA standards exposes an employer to civil and criminal liability. Not only does noncompliance lead to OSHA liability, a party may use it as evidence of negligent or reckless conduct in a subsequent lawsuit.

Responding to COVID-19

Under the OSH Act, employers are responsible for providing a safe and healthy workplace free from recognized hazards likely to cause death or serious physical harm. On January 29, 2021, the Occupational Safety and Health Administration (OSHA) released updated guidance to assist most employers and workers with implementing a coronavirus prevention program and mitigating the risk of the spread of coronavirus. The guidance titled, “Protecting Workers: Guidance on Mitigating and Preventing the Spread of COVID-19 in the Workplace” (Guidance) was prepared to comply with President Biden’s Executive Order issued on January 21, 2021, directing the federal government to take “swift action to reduce the risk that workers may contract COVID-19 in the workplace.” This Guidance was last updated on August 13, 2021.The Guidance is advisory in nature and creates no new legal obligations in the form of an OSHA standard or regulation.

Many of the elements may have already been implemented. Employers should take note of the recommendations, which include:

- Facilitate employees getting vaccinated. It is suggested that employers grant paid time off for employees to get vaccinated and recover from any side effects or consider working with local public health authorities to provide vaccinations in the workplace for unvaccinated workers. OSHA further suggests that employers consider adopting policies that require workers to get vaccinated or to undergo regular COVID-19 testing – in addition to mask wearing and social distancing – if they remain unvaccinated.

- Instruct any workers who are infected, unvaccinated workers who have had close contact with someone who tested positive for SARS-CoV-2, and all workers with COVID-19 symptoms to stay home from work to prevent or reduce the risk of transmission of the virus that causes COVID-19.

- Implement physical distancing in all communal work areas for unvaccinated and otherwise at-risk workers. A key way to protect such unvaccinated workers is to physically distance them from other such people (workers or customers) – generally at least six feet of distance is recommended, although this is not a guarantee of safety, especially in enclosed or poorly ventilated spaces. Employers might also consider limiting the number of unvaccinated or otherwise at-risk workers in one place at any given time, for example by implementing flexible worksites (e.g., telework); implementing flexible work hours (e.g., rotate or stagger shifts to limit the number of such workers in the workplace at the same time); delivering services remotely (e.g., phone, video or web); or implementing flexible meeting and travel options, for such workers.

- Provide workers with face coverings or surgical masks,4 as appropriate, unless their work task requires a respirator or other PPE. In addition to unvaccinated and otherwise at-risk workers, CDC recommends that even fully vaccinated people wear masks in public indoor settings in areas of substantial or high transmission and notes that fully vaccinated people may appropriately choose to wear masks in public indoor settings regardless of community level of transmission, particularly if they are at risk or have someone in their household who is at risk or not fully vaccinated.

Workers should wear a face covering that covers the nose and mouth to contain the wearer's respiratory droplets and to help protect others and potentially themselves. Face coverings should be made of at least two layers of a tightly woven breathable fabric, such as cotton, and should not have exhalation valves or vents. They should fit snugly over the nose, mouth and chin with no large gaps on the outside of the face.

OSHA recommends employers provide face coverings to workers who request them at no cost (and make replacements available to workers when they request them). Under federal anti-discrimination laws, employers may need to provide reasonable accommodations for any workers who are unable to wear or have difficulty wearing certain types of face coverings due to a disability or who need a religious accommodation under Title VII of the Civil Rights Act. In workplaces with employees who are deaf or hard of hearing, employers should consider acquiring masks with clear coverings over the mouth to facilitate lip-reading.

For operations where the face covering can become wet and soiled, employers are encouraged to provide workers with replacements daily or more frequently, as needed. Face shields may be provided for use with face coverings to protect them from getting wet and soiled.

Employers with workers in a setting where face coverings may increase the risk of heat-related illness indoors or outdoors or cause safety concerns due to introduction of a hazard (for instance, straps getting caught in machinery) may wish to consult with an occupational safety and health professional to help determine the appropriate face covering/respirator use for their setting.

- Educate and train workers on your COVID-19 policies and procedures using accessible formats and in languages they understand. Train managers on how to implement COVID-19 policies. Communicate supportive workplace policies clearly, frequently, and via multiple methods to promote a safe and healthy workplace. Communications should be in plain language that unvaccinated and otherwise at-risk workers understand (including non-English languages, and American Sign Language or other accessible communication methods, if applicable) and in a manner accessible to individuals with disabilities. Training should be directed at employees, contractors, and any other individuals on site, as appropriate, and should include:

- basic facts about COVID-19, including how it is spread and the importance of physical distancing (including remote work), ventilation, vaccination, use of face coverings, and hand hygiene

- workplace policies and procedures implemented to protect workers from COVID-19 hazards.

In addition, ensure that workers understand their rights to a safe and healthful work environment, whom to contact with questions or concerns about workplace safety and health, and their right to raise workplace safety and health concerns free from retaliation. (See Implementing Protections from Retaliation, below.) This information should also be provided in a language that workers understand. Ensure supervisors are familiar with workplace flexibilities and other human resources policies and procedures.

- Suggest or require that unvaccinated customers, visitors or guests wear face coverings in public-facing workplaces such as retail establishments, and that all customers, visitors, or guests wear face coverings in public, indoor settings in areas of substantial or high transmission. This could include posting a notice or otherwise suggesting or requiring that people wear face coverings, even if no longer required by your jurisdiction. Individuals who are under the age of two or are actively consuming food or beverages on site need not wear face coverings.

- Maintain ventilation systems. The virus that causes COVID-19 spreads between people more readily indoors than outdoors. Improving ventilation is a key engineering control that can be used as part of a layered strategy to reduce the concentration of viral particles in indoor air and the risk of virus transmission to unvaccinated and otherwise at-risk workers in particular. A well-maintained ventilation system is particularly important in any indoor workplace setting and when working properly, ventilation is an important control measure to limit the spread of COVID-19. Adequate ventilation will protect all people in a closed space. Key measures include ensuring heating, ventilation and air conditioning (HVAC) systems are operating in accordance with the manufacturer’s instructions and design specifications, conducting all regularly scheduled inspections and maintenance procedures, maximizing the amount of outside air supplied, installing air filters with a Minimum Efficiency Reporting Value (MERV) 13 or higher where feasible, maximizing natural ventilation in buildings without HVAC systems by opening windows or doors, when conditions allow (if that does not pose a safety risk), and considering the use of portable air cleaners with High Efficiency Particulate Air (HEPA) filters in spaces with high occupancy or limited ventilation.

- Perform routine cleaning and disinfection. If someone who has been in the facility within 24 hours is suspected of having or confirmed to have COVID-19, follow the CDC cleaning and disinfection recommendations. Follow requirements in mandatory OSHA standards 29 CFR 1910.1200 and 1910.132, 133, and 138 for hazard communication and PPE appropriate for exposure to cleaning chemicals.

- Record and report COVID-19 infections and deaths.

- Follow other applicable mandatory OSHA standards: All of OSHA's standards that apply to protecting workers from infection remain in place. These mandatory OSHA standards include: requirements for PPE (29 CFR part 1910, Subpart I (e.g., 19132 and 133)), respiratory protection (29 CFR 19134), sanitation (29 CFR 19141), protection from bloodborne pathogens: (29 CFR 191030), and OSHA's requirements for employee access to medical and exposure records (29 CFR 191020). Many healthcare workplaces are covered by the mandatory OSHA COVID-19 Emergency Temporary Standard. More information on that standard is available on OSHA's website at:

- https//osha.gov/coronavirus/safework

Employers are also required by the General Duty Clause, Section 5(a)(1) of the OSH Act, to provide a safe and healthful workplace free from recognized hazards that are causing or likely to cause death or serious physical harm.

Workplaces with mixed-vaccination status workers

It is recommended that employers should take additional steps to mitigate the spread of COVID-19 among unvaccinated or otherwise at-risk workers due to the following types of workplace environmental factors, especially in locations of substantial or high transmission:

• Close contact – where unvaccinated and otherwise at-risk workers are working close to one another, for example, on production or assembly lines or in busy retail settings. Such workers may also be near one another at other times, such as when clocking in or out, during breaks, or in locker/changing rooms.

• Duration of contact – where unvaccinated and otherwise at-risk workers often have prolonged closeness to coworkers (e.g., for six to 12 hours per shift).

• Type of contact – where unvaccinated and otherwise at-risk workers may be exposed to the infectious virus through respiratory particles in the air – for example, when infected workers in a manufacturing or factory setting cough or sneeze, especially in poorly ventilated spaces.

In all workplaces with heightened risk due to workplace environmental factors where there are unvaccinated or otherwise at-risk workers in the workplace:

- Stagger break times in these generally high-population workplaces, or provide temporary break areas and restrooms to avoid groups of unvaccinated or otherwise at-risk workers congregating during breaks. Such workers should maintain at least 6 feet of distance from others at all times, including on breaks.

- Stagger workers' arrival and departure times to avoid congregations of unvaccinated or otherwise at-risk workers in parking areas, locker rooms, and near time clocks.

- Provide visual cues (e.g., floor markings, signs) as a reminder to maintain physical distancing.

- Require unvaccinated or otherwise at-risk workers, and also fully vaccinated workers in areas of substantial or high community transmission, to wear masks whenever possible, encourage and consider requiring customers and other visitors to do the same.

- Implement strategies (tailored to your workplace) to improve ventilation.

In high-volume retail workplaces (or well-defined work areas within retail workplaces) where there are unvaccinated or otherwise at-risk workers, customers or other people:

- Ask customers and other visitors to wear masks, especially in areas of substantial or high transmission.

- Consider ways to promote physical distancing between unvaccinated or otherwise at-risk people and/or limiting occupancy to allow for physical distancing consistent with CDC guidance.

- Move the electronic payment terminal/credit card reader farther away from unvaccinated and otherwise at-risk workers in order to increase the distance between customers and such workers if possible.

- Adjust stocking activities to limit contact between unvaccinated and otherwise at-risk workers and customers.

Unvaccinated or otherwise at-risk workers are also at risk when traveling to and from work in employer-provided buses and vans.

- Notify unvaccinated and otherwise at-risk workers of this risk and, to the extent feasible, help them limit the number of such workers in one vehicle.

- Make sure all unvaccinated and otherwise at-risk workers sharing a vehicle are wearing appropriate face coverings. Make sure all workers wear appropriate face coverings in areas of substantial or high community transmission.

- Where not prohibited by weather conditions, open vehicle windows.

In meat, poultry and seafood processing settings; manufacturing facilities; and assembly line operations (including in agriculture) involving unvaccinated and otherwise at-risk workers:

- Ensure adequate ventilation in the facility, or if feasible, move work outdoors.

- Space such workers out, ideally at least six feet apart, and ensure that such workers are not working directly across from one another. Barriers are not a replacement for worker use of face coverings and physical distancing.

- If barriers are used where physical distancing cannot be maintained, they should be made of a solid, impermeable material, like plastic or acrylic, that can be easily cleaned or replaced. Barriers should block face-to-face pathways and should not flap or otherwise move out of position when they are being used.

- Barriers do not replace the need for physical distancing – at least six feet of separation should be maintained between unvaccinated and otherwise at-risk individuals whenever possible.

Additional resources

In addition, OSHA has issued alerts in both English and Spanish to provide guidance to the employer community. These are accessible on the OSHA website at:

and include:

- Prevent Worker Exposure to Coronavirus (COVID-19). (March 2020).

- Retail Workers (April 8, 2020).

- Package Delivery Workforce (April 13, 2020).

- Manufacturing Industry Workforce (April 16, 2020).

- Construction Workforce (April 21, 2020).

- Restaurants & Beverage Vendors Offering Takeout or Curbside Pickup (May 1, 2020).

- Dental Practitioners (May 11, 2020).

- Retail Pharmacies (May 14, 2020).

- Rideshare, Taxi, and Car Service Workers (May 14, 2020).

- Nursing Home and Long-Term Care Facility Workers (May 14, 2020).

- Social Distancing at Work (May 28, 2020).

- Stockroom and Loading Dock Workers (June 2, 2020).COVID-19 Guidance for Hair and Nail Salon Workers (August 18, 2020).

- COVID-19 Guidance for Food Truck Workers (August 18, 2020).

- COVID-19 Guidance for In-Home Repair Services (October 7, 2020).

- COVID-19 Guidance for Restaurants Resuming Dine-In Service (October 7, 2020).

- COVID-19 Guidance on Ventilation in the Workplace (November 4, 2020).

High-risk materials

As noted at the beginning of this chapter, the Massachusetts Division of Occupational Safety (DOS) also enforces state regulations concerning workplace health and safety. The agency’s general mission is to protect workers’ safety, health, wages, and working conditions. In addition to its general health and wage oversight, DOS enforces regulations pertaining to asbestos and lead.

General health and wage oversight

DOS provides a free consultation service to assist employers in recognizing and controlling safety and health hazards in the workplace and improving their safety programs. It also assists employers to train employees and, in some cases, to qualify for a one-year exemption from routine OSHA inspections. The service is jointly funded by DOS and DOL, and targets smaller businesses (those with fewer than 250 employees per establishment or 500 employees nationwide) in high-hazard industries, such as manufacturing, healthcare, and construction. This is a confidential service, in which the employer may provide its name and any information concerning healthy working conditions, and it will not be reported routinely to the OSHA inspection staff.

In addition, DOS administers the Commonwealth’s minimum wage law, and issues prevailing wage schedules to cities, towns, counties, districts, authorities, and agencies for construction projects and other types of public work. The prevailing wage schedules include the hourly wage rates that workers must receive when working on a public project.

Asbestos and lead

The DOS regulates occupational asbestos exposure and lead handling. The agency’s regulations impose a number of requirements on employers that handle these substances.

Licenses and certifications

Massachusetts law requires any entity that handles asbestos or lead to obtain a license. The respective applications require the entity to submit a number of additional documents with the application, including copies of specific policies governing its protection of employees who handle the substances (such as a respirator program in the case of asbestos).

License applications are available at:

In addition to licensing requirements, DOS requires certain asbestos workers become certified by DOS to handle asbestos. These workers requiring certification include:

- asbestos workers and supervisors

- contractors (entities or individuals who provide asbestos counseling services)

- training providers (individuals who train others in the proper handling of asbestos)

- analytical services (services that analyze asbestos content in connection with any hazard assessment, building inventory, exposure measurement, abatement project or associated project).

Training requirement

Any individual that handles asbestos or lead must complete periodic training provided by a certified training provider. The requirements of the training depend on the employee’s position. An individual worker (not a supervisor or trainer), must complete an approved four-day training course which should include:

- lectures

- demonstrations

- at least 14 hours of hands-on training

- respirator fit testing

- course review

- a written examination of 50 multiple choice questions.

Notifications

Any employer that handles asbestos or lead must notify DOS before engaging in certain projects. It must provide this notification at least 10 days before the project starts or, in the case of an emergency project, within one working day after starting.

Recordkeeping

Any entity that handles asbestos or lead must maintain certain records concerning its employees’ trainings and asbestos notifications, among other things. The entity must make these records available to the Director of DOS upon request. Moreover, in the case of asbestos, the entity must retain these documents for a period of 30 years from the date of project or activity completion. Records related to lead program compliance must be retained for 10 years.

Cease and desist orders

When DOS determines that there is a violation of a workplace standard that compromises the protection of the general public or of workers, or of any standard or requirement for licensure, it may order the worksite to be closed. The worksite may include the area where asbestos-related work is performed and other areas of the facility that DOS determines may be hazardous.

Fines

Any entity that violates the asbestos or lead regulations may be subject to a fine of between $500 and $1500 for each offense.

On-site inspections

OSHA compliance officers may conduct on-site inspections and interviews to determine whether an employer complies with the OSH Act. During an inspection, an OSHA inspector may privately question hourly employees, however, he or she may not insist on private interviews with management or supervisory personnel. In the event that a manager or supervisor meets with an OSHA inspector, he or she should be accompanied by a witness. When an employer fails to cooperate with a request for interviews or records, OSHA may issue a subpoena to obtain the information.

Advance notice

An OSHA officer typically conducts an inspection without advance notice, but it must conduct it at a reasonable time, in a reasonable manner, and within reasonable time limits. Any individual who gives an employer advance notice of an OSHA inspection may be subject to criminal penalties.

Search warrants

An employer has the right to require an OSHA inspector to obtain a search warrant before entering the workplace. However, a search warrant is easy to obtain and may lead to a more meticulous inspection.

OSHA inspections typically include four steps:

- presentation of inspector credentials

- introductory conference to explain the reason for the inspection as well as the purpose, scope, and procedure of the inspection

- inspection walk

- final conference to discuss hazardous conditions and potential violations in the workplace as well as to inform the employer of his rights and obligations.

To the extent possible, an employer should prepare for an OSHA inspection. Before an inspection takes place, the employer should decide whether it will require a warrant and who should accompany the inspector on the walk.

Penalties for violations

Violations of the OSH Act expose employers to the risk of civil and criminal penalties. The amount of each penalty depends on the nature of the corresponding violation. In addition, the Department of Justice may bring a criminal action against an employer for certain, specific misconduct or for willful violations that lead to death.

OSHA citations and penalties

OSHA has the authority to propose penalties for violations of the OSH Act. OSHA determines the amount of the penalty based on the nature and circumstances of the violation. Violations and the corresponding penalties fall into six general categories:

- Other-than-serious - This category includes violations that would not cause death or serious physical harm, but nonetheless relate to job safety and health. Each violation may carry a penalty of up to $15,625.

- Serious - This category includes violations with a substantial probability of death or serious injury where the employer knew or should have known of the hazard. Each serious violation may carry a penalty of up to $15,625.

- Willful - This category includes violations that the employer intentionally and knowingly commits as well as violations committed with a plain indifference to the law. A violation is committed with plain indifference to the law where an employer is aware of a hazard but makes no reasonable efforts to eliminate the hazard. Each willful violation may carry a penalty of up to $156,259, with a minimum penalty of $5,000. Additionally, a willful violation resulting in the death of an employee may expose an employer to criminal liability.

- Repeated - This category includes violations when OSHA finds a substantially similar violation upon reinspection. However, citations under contest may not form the basis for a subsequent repeated citation. Each repeated violation may carry a penalty of up to $156,259

- Failure to correct cited violations - This category applies where employers fail to correct cited violations by the deadline (the “abatement deadline”). Each violation that an employer fails to correct may carry a penalty of up to $15,625 for each day beyond the abatement deadline.

- Violating posting requirements - Violations of posting requirements may carry a penalty of up to $15,625.

Amount of penalty

OSHA may reduce the amount of a penalty depending on the circumstances. Moreover, OSHA will not propose a penalty when it reduces the penalty below $100.

The factors used by OSHA to reduce penalties are the:

- size of the employer’s business

- employer’s good faith as determined by efforts to comply with the OSH Act, such as cooperation with OSHA personnel, quality of safety programs, and diligence in correcting hazards

- employer’s history of previous violations

- gravity of the violation when the alleged violation is serious as determined by the number of employees exposed to the hazard, the frequency and duration of these exposures, and the risk of death or serious injury.

Criminal penalties

The OSH Act authorizes criminal penalties, including fines and jail time, for:

- willful violations leading to death

- falsifying records, reports, or applications

- interfering with a compliance officer in the performance of his or her duties.

Criminal convictions under the OSH Act carry up to six months of imprisonment.

Contesting a citation

If an employer disagrees with an OSHA citation, it may challenge it by filing a “notice of contest” within 15 days from the date the employer receives the citation. There is no specific format for the notice of contest, but it must clearly identify the basis for contesting the citation.

During the 15-day window, the employer may request an informal conference with the area director to compromise on the citations before proceeding to litigation. If no compromise is reached (or if the employer decides to forego the informal conference), the employer must file the written notice of contest to commence the appeal process.

Alternately, if an employer agrees with the citation, but cannot meet the abatement deadline in the citation, the employer may file a petition for modification of abatement. The employer must file this written petition with the area director no more than one working day after the original abatement date.

After the employer files a notice of contest, OSHA refers the matter to the Office of Solicitor for the U.S. Department of Labor and to the Occupational Safety and Health Review Commission (OSHRC), which is the tribunal that adjudicates the contested citation. The case then proceeds to an administrative proceeding and, absent settlement, concludes with a hearing much like a trial, after which an administrative law judge decides the case. The employer may request that the OSHRC review the final decision. Finally, when the OSHRC issues its ruling, the employer may appeal it in federal court.

Employer defenses

An employer may raise a number of defenses to a citation, penalty, abatement deadline, or method of correcting a violation. The employer should raise its defenses when it challenges the alleged violation. These are common employer defenses to OSHA citations:

- No violation - This defense applies when the employer has not violated the applicable standard, general duty clause, or regulation alleged in a citation.

- No hazard - This defense applies when a violation occurs but no hazard resulted from the violation. Accordingly, it applies in situations where the employer did not expose the condition to its employees or where the employer reasonably had no knowledge of the violation.

- De minimis violation - This defense applies when an employer violates an OSHA standard or policy, but did not create a hazard or otherwise compromise workplace health and safety conditions. In addition, this defense applies to minor, technical violations of the OSH Act when the employer provided adequate alternative protections. There is no penalty for a de minimis violation.

- Defenses related to the applicable standard - An employer may contend that the applicable standard is ambiguous, improperly applied, or non-binding on the employer. When an employer challenges the wording of a standard, it must be so ambiguous that a reasonable person would not know what type of conduct the standard prohibits. A non-binding standard is one that amounts to a mere suggestion rather than a requirement.

- Feasibility of compliance - An employer may contend that it cannot meet a standard, regulation, or the general duty clause by any known, available and feasible means of compliance. This defense also applies where the abatement deadline or method is unreasonable. However, an employer may have difficulty establishing this type of defense. To assert it, an employer must demonstrate that it applied all alternative means of correction that are known and feasible.

The employer must also demonstrate that it is not lagging behind industry-standards of compliance. The cost of compliance is not a feasibility defense except in limited, extreme circumstances. - Employee misconduct - An employer may have a defense when non-compliance resulted from employee misconduct. To use this defense, the employer must establish that the employee did not follow previously established and enforced work rules or otherwise acted in an unpredictable manner. Moreover, the employee’s misconduct must be reasonably unanticipated. Ultimately, employers must demonstrate rigorous enforcement of safety rules and adequate employee safety training to assert the employee misconduct defense.

- Miscellaneous defenses - Employers may have a defense where:

- a citation was not issued within 180 days

- a citation resulted from an illegal inspection, or OSHA’s evidence of a violation is unconvincing or not credible

- the employer cited did not create the hazard, had no power to correct it, or had no employees exposed to it

- OSHA does not have jurisdiction over the condition cited.